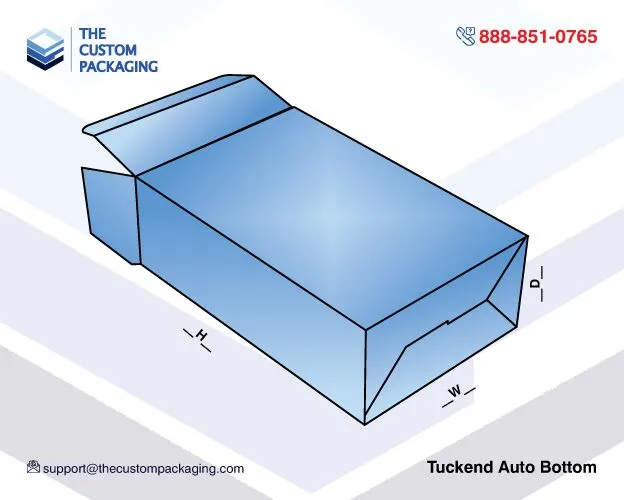

Tuck End Auto Bottom

Get a Free Quote

- Details

- Specification

Custom designed tuck end auto bottom boxes provided by The Custom Packaging UK offer extra support to inside products because they are manufactured with the best quality paper materials known for their durability and strength.

Strong Materials

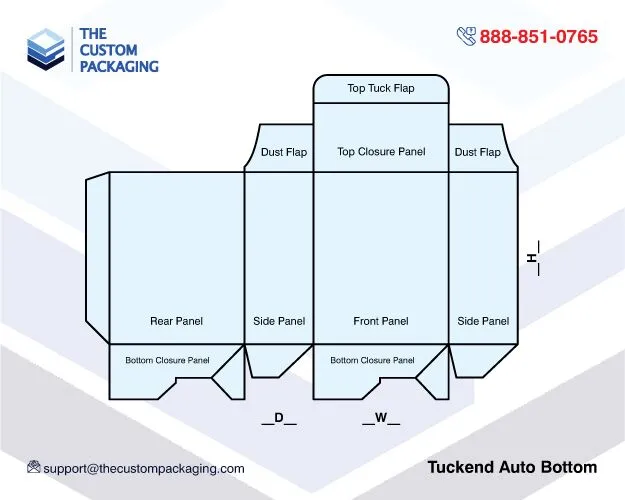

Tuck end auto-bottom design of packaging boxes is already sufficient to ensure product protection. But, the shape, size, style, and thickness of packaging boxes are also a matter of concern. Therefore, we use the most reliable paper materials to customise packaging per the requirements of your products. Whether you want these boxes to display, ship, or store products, customised tuck end auto bottom boxes are suitable for all packaging needs. Tell us your specifications regarding these boxes so that we can manufacture them accordingly using strong and flexible paper materials like

- Kraft

- Cardstock

- Cardboard

- Corrugated paper

Extra Protection

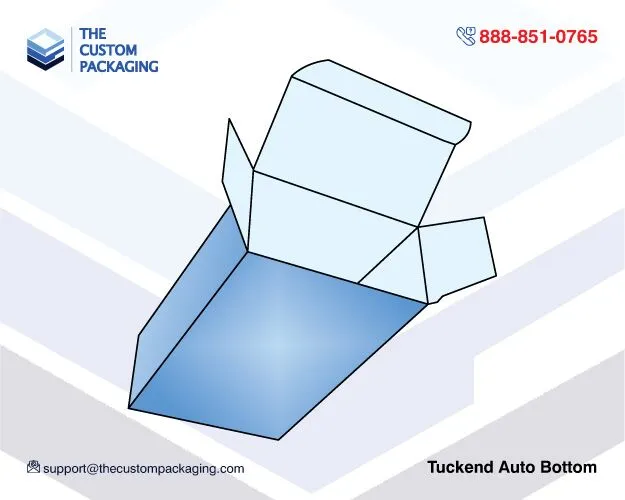

Our top priority is to make rigid tuck-end packaging boxes to make them capable of protecting whatever is packaged inside. We make durable tuck end auto bottom boxes with strong paper materials and glues/adhesives. Besides that, the latest die-cut equipment is being used to make these boxes as accurate as they are intended to be. Auto bottom boxes are manufactured with strong yet flexible materials to shape and customise them per your needs. Each packaging box is pre-glued making it easy to assemble in time of need. We ship tuck-end packaging boxes flat to ensure that boxes remain in pristine condition and also decrease packaging volume.

Marketing and Customisation

The Custom Packaging UK is here with all the latest customisation techniques to provide personalised tuck end boxes. Customisation of packaging boxes with branding contents like logos, taglines, product descriptions, and brand details makes them very effective in business marketing. From paper materials to surface finishes, our customers select everything per their needs. One can get customised tuck end auto bottom packaging in custom colours, prints, and coats. With advanced printing, colouring, and die-cut equipment, we provide tailor-made tuck-end boxes to provide aesthetic product displays that highlight product features. As custom-printed tuck-end packaging contains product details along with brand info, it is the perfect representation of your brand. We also provide support from expert designers to help you customise trendy tuck-end boxes.

Versatile Designing Options

Our expert team has access to all the tools to design and manufacture packaging boxes of your choice. The customised boxes stand out on the shelve of stores when designed using the latest colouring, printing, embossing, foiling, and coating techniques. Made-to-order tuck-end packaging is not the identity of your brand in terms of colours and prints. Therefore, we offer versatile designing possibilities to help you design the most distinctive tuck end auto bottom boxes that outshine your competitors. Gold/silver foiling creates a metallic shine on the packaging. Embossing and debossing techniques give raised or recessed effects. One can apply a glossy or matt coating to a sleek and premium touch. Thus, call us now to get these boxes designed per your requirements.

| Dimensions | All Custom Sizes & Shapes |

| Printing | CMYK, PMS, No Printing |

| Paper Stock | 10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities | 100 - 500,000 |

| Coating | Gloss, Matte, Spot UV |

| Default Process | Die Cutting, Gluing, Scoring, Perforation |

| Options | Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof | Flat View, 3D Mock-up |

| Turn Around Time | 10-12 Business Days , Rush |

Frequently Asked Questions

Got a question? Take a look at our FAQs about The Custom Packaging UK process. If you can't find the answer you're looking for, don't hesitate to contact us through live chat, one of our online forms, or give us a call at 0800 047 8188 to speak with a custom box packaging expert now.

How does the auto bottom feature benefit quick assembly and packaging?

Is a tuck end auto bottom box strong enough for heavier products?

What industries most commonly use tuck end auto bottom boxes?

Can I include product windows or cut-outs on a tuck end auto bottom box?

How does this box style perform in automated packaging lines?

What customisation options are available for the bottom flaps?

Cosmetic Packaging

Cosmetic Packaging Display Packaging

Display Packaging CBD Packaging

CBD Packaging Retail Packaging

Retail Packaging Product Packaging

Product Packaging Cigarette Packaging

Cigarette Packaging Candle Packaging

Candle Packaging Soap Packaging

Soap Packaging Chocolate Packaging

Chocolate Packaging Vape Packaging

Vape Packaging Food Packaging

Food Packaging Gift Packaging

Gift Packaging Bakery Packaging Boxes

Bakery Packaging Boxes Pizza Packaging

Pizza Packaging Bottle Packaging

Bottle Packaging Garments Packaging

Garments Packaging Custom Printed Bags

Custom Printed Bags Christmas Packaging

Christmas Packaging Toy Packaging

Toy Packaging Cereal Packaging

Cereal Packaging jewellery Packaging

jewellery Packaging Apparel Packaging

Apparel Packaging Shipping Packaging

Shipping Packaging Custom Pre Roll Boxes

Custom Pre Roll Boxes Dispenser packaging

Dispenser packaging Eco Friendly Packaging

Eco Friendly Packaging Custom Health Packaging

Custom Health Packaging Pharmaceutical Packaging

Pharmaceutical Packaging